AN INDEPTH REVIEW OF SCAM PROJECTS

I hired SCAM to rebuild my deck and install a front entry door. To his credit, he did do two extras things and did not charge me extra to do them. And, these outcomes were very good. He, at no extra charge, removed a small section (about 10 ft.) of fencing and power washed my cast iron patio furniture. At the end of the day, however, I would have been better off financially hiring someone else to do these menial tasks than it will cost me to fix the problems caused by flaws in his workmanship on the deck and front entry door. So, if you need menial tasks done, Sellers can do it. However, if you are considering him for major projects - buyer beware!!!

One would think that someone with 25 years carpentry experience would be able to install a pre-hung door correctly. Such is not the case with SCAM. As you view the following pictures, keep in mind that this is a pre-hung door and the door was square in the frame upon arrival from Menard's.

AT FIRST GLANCE

Figure 1

Immediately after the installation of the door, I pointed out to SCAM that the door was not level. He instantly became very defensive and confrontational. Figure 1 clearly shows that the door is not square in the frame; and, this fact is obvious to everyone but the blind; and, even they can feel the air around the door.

SCAM FALSELY BLAMES MANUFACTURER DEFECT

Figure 2

I insisted that the door was not level and told SCAM that is was so far off that I could see outdoors through the upper right hand corner. SCAM opened the door, looked around, then cunningly claimed that the problem was a wrinkle in the insulation (illustrated in Figure 2) and "that's on them," he said. His claim is physically impossible since the insulation wrinkle cannot offset the door's horizontal balance because it is not above the door; but, it is rather parallel to it. Keep reading for more details.

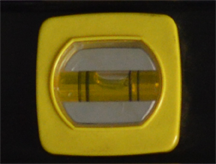

FACT: THE DOOR IS NOT LEVEL

Figure 3

Figure 4

Figure 3 shows that the door frame header is level.

Figure 4 shows that the door is NOT level.

PROBLEMS CREATED DURING REMOVAL AND RE-INSTALLATION OF THE STORM DOOR

Figure 5

Figure 6

Figure 7

When SCAM removed the storm door, he laid it on my front lawn. Figure 5 shows how this action scorched the lawn.

Then, the storm door was not re-installed correctly leaving gaps at both the top and bottom as illustrated by Figures 6 and 7, respectivley.

Due to the unlevel entry door and poor re-installation of the storm door, my electricity usage increased sharply.

SERIOUS PROBLEMS WITH THE DECK

Figure 8

Figure 9

The first two times ascending the stairs, I tripped when stepping onto the deck from the last stair. I told SCAM that the rise onto the deck must be higher than the rise on other steps. SCAM scoffed at my claim and asserted that they were all 7-1/4 inches. Well, the illustrations on the left proves that I was right and SCAM was wrong.

Figure 8 shows that the rise between stairs is 7 inches (not 7-1/4 as SCAM asserted). However, Figure 9 shows that the rise from the last stair to the deck is a whopping 9-5/16 inches!!!

This is definitely a trip hazard and a violation of building code.

MORE PROBLEMS WITH THE DECK

The first time descending the stairs, holding onto the handrail (see Figure 10), I got a splinter (or sliver, if you will) in my hand from the ragged edges. After that, I found more ragged edges. Some are shown in Figures 10, 11, and 12. But, there are many, many more that pose splinter hazards.